Now that we know there's a solution let's take a look at the benefits of implementing energy efficient fixtures in hazardous areas.

I have worked on numerous chemical process structures and it is not uncommon for them to have 50+ fixtures in a multi level structure.

Typically these fixtures are 175W Metal Halide, the fixtures that are in difficult to reach areas typically have burned out lamps or ballasts causing possible safety issues.

Cost to Operate 175 Watt Metal Halide Fixtures

For an example we will use 60 of these fixtures.

(60 X 182W = 10,920W) /1000 = 10.92KW

10.92W X 4015 hrs = 43844 KWH (4015 is annual hours of usage)

43844 KWH X .11 =

$4,822.84 a year to run (.11 is electric rate)

Cost to Operate 85 Watt Inductive Fixture-Hazardous Location

Take the same formula and use the new 85W fixture:

60 X 85W = 5100W) /1000 = 5.1KW

5.1KW X 4015 hrs = 20476 KWH (4015 is annual hours of usage)

20476 KWH X .11 =

$2,252.36 a year to run (.11 is electric rate)

So in a small 60 fixture structure I reduced the cost of lighting the structure by 50%.

Apply that to large chemical plant campuses or industrial campuses and the savings would be staggering since most of these facilities have thousands of these types of lights.

Reduced Maintenance:

Remember I made mention of the metal halide lights being burned out?

It's not by choice, but a lot of these fixtures are located in hazardous areas that are difficult to work in.

Compile that with the short life of metal halide lamps and you quickly see your fighting a losing battle.

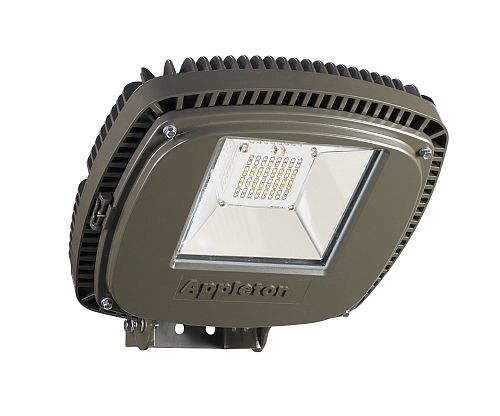

The new generation of Inductive Fluorescent fixtures from Appleton offer 100,000 hr lamp life and yet the lamp itself only has a 30% depreciation in light output after 60,000 hrs.

Comparing that to metal halide it's easy to see that the days of little or no light in crucial areas when it's dark would be gone.

Reducing Costs:

Owners of these types of facilities already utilize VFD's to try and make there processes as efficient as possible, I can't say that I blame them, every dollar they spend on electricity to make there product is one less in their pocket.

Not much in industry is controllable, raw material costs fluctuate, and energy costs are rising.

By utilizing new lighting technology, implementing VFD's and installing new energy efficient motors you can take a substantial chunk out of your operational costs for years to come.

How Much Could You Save?

Interested in finding out how much you could save?

Schedule a FREE Evaluation of your facility today. No cost, No fuss, No pressure just a quick evaluation to see if you could be saving 50% today! You can't afford to wait....

Comment below on the types of hazardous environments you would like to light up.

Most Popular Posts

Latest Posts